Introduction

CO2 laser cutting machines stand out as transformative wizards, leaving an indelible mark on industries far and wide. As we embark on this exploration, envision the powerful impact and unparalleled versatility these machines bring to the forefront of modern manufacturing. These are not just tools; they are the architects of precision and the conduits of creativity, reshaping the landscape of various industries.

A succinct introduction to the significance of CO2 laser cutters sets the stage for a journey into the heart of precision engineering. These machines are not mere instruments; they are the architects of meticulous designs and the catalysts for efficient, high-quality production. Their role in various industries is not just pivotal but revolutionary, ushering in an era where the fusion of technology and craftsmanship knows no bounds.

Understanding CO2 Laser Cutting Machines

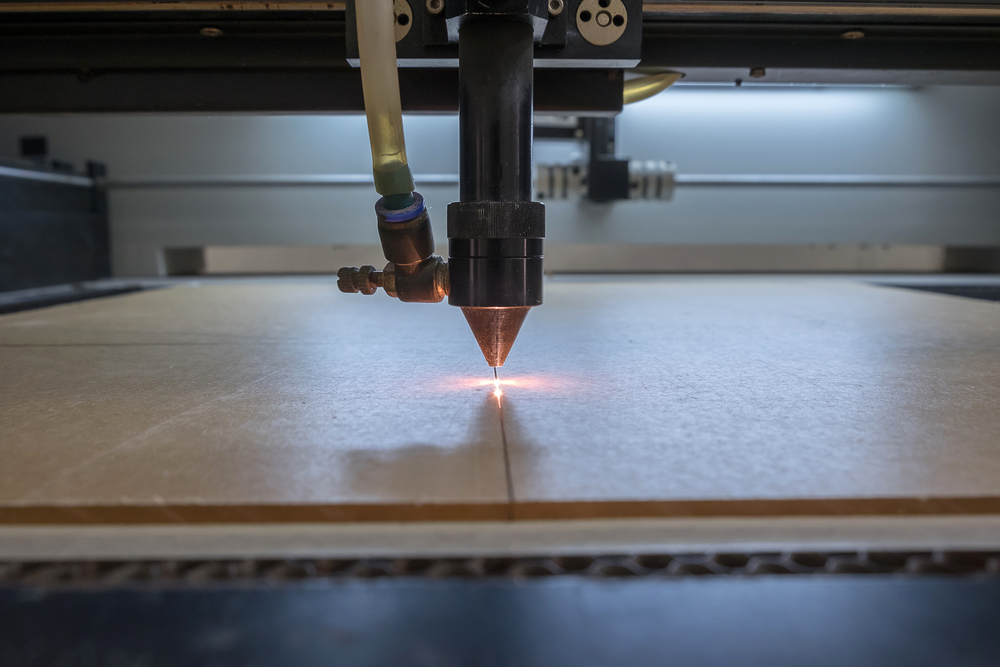

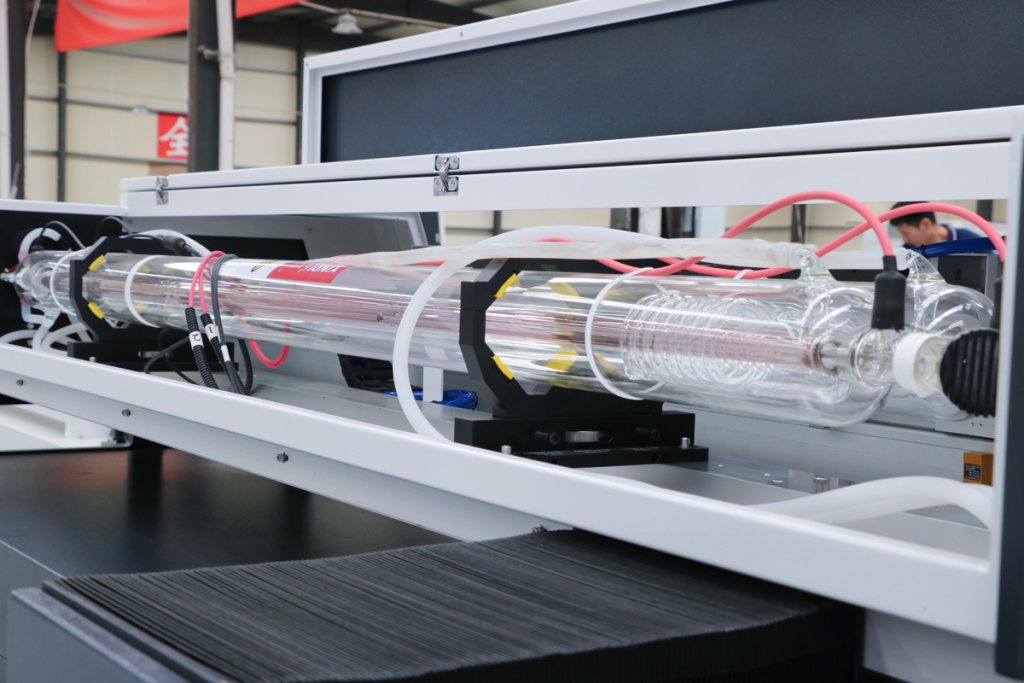

At the core of CO2 laser cutting machines lies a simple yet mesmerizing operational principle. Imagine a concentrated beam of light, harnessed and directed with precision. Our exploration will demystify this technology, functionalities that make CO2 laser cutting a technological marvel.

Without delving into the intricacies that may overwhelm, our aim is to elucidate the essence of CO2 laser technology. Picture a dance of photons and mirrors, a symphony of precision, as we highlight the diverse applications and creative avenues these machines open. From intricately carving through materials to etching designs with unmatched accuracy, CO2 laser cutting transcends the boundaries of conventional craftsmanship.

This understanding forms the foundation for an exploration that goes beyond the technical jargon, inviting readers into a world where laser beams sculpt art and engineering converges with artistry.

Advantages of CO2 Laser Cutting

Embarking on a journey through the advantages of CO2 laser cutting machines is like uncovering a treasure trove of possibilities. These machines, with their precision and versatility, herald a new era in manufacturing, leaving traditional methods in their wake.

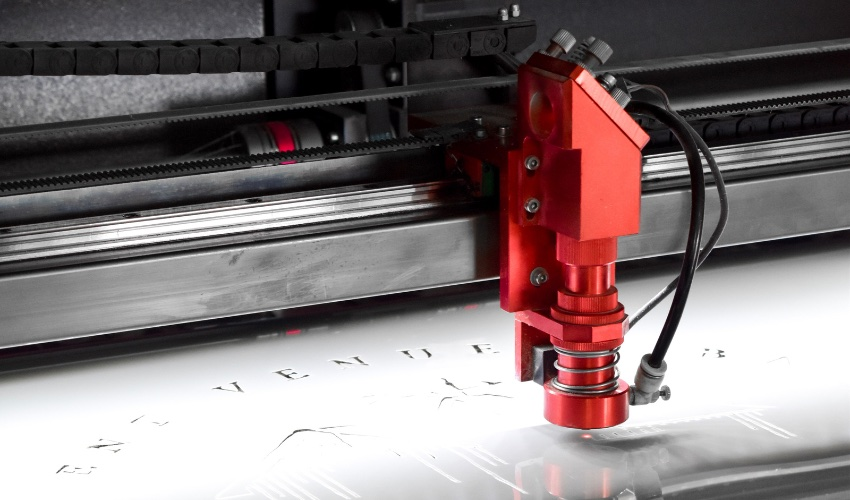

Picture this: intricate designs etched flawlessly onto materials, swift and accurate cuts through various substances, and the ability to achieve complex patterns with unparalleled finesse. CO2 laser cutting machines redefine precision, offering a level of accuracy that surpasses conventional methods.

Real-life examples paint a vivid picture, ranging from automotive to fashion, have witnessed a surge in efficiency and quality. In the automotive sector, custom parts are crafted with meticulous accuracy, reducing production times and ensuring a perfect fit. Fashion designers embrace these machines to create intricate patterns and details on fabrics, pushing the boundaries of design possibilities.

Let’s outline these advantages:

- Versatility in Materials: From metals to fabrics and everything in between, these machines effortlessly navigate through a myriad of materials, expanding the scope of creative possibilities.

- Time-Efficient Production: Swift and precise, CO2 laser cutting reduces production times significantly, making it a preferred choice for industries where efficiency is paramount.

- Customization at Its Peak: Realize personalized designs with ease, whether it’s crafting bespoke furniture or engraving intricate details on promotional items.

- Minimal Material Waste: The focused laser beam minimizes material wastage, contributing to a more sustainable and eco-friendly production process.

Exploring Challenges in the Realm of CO2 Laser Cutting

Embarking on a journey through the intricacies of CO2 laser cutting unveils a tapestry woven with innovative brilliance, yet, like any technological marvel, it carries its set of challenges. Let’s navigate these nuances with a discerning eye, offering insights into scenarios where alternative methods might gracefully step into the spotlight.

Balancing Realism with Insightful Perspective

- Intricacies of Maintenance: The symphony of a CO2 laser cutting machine, while mesmerizing, demands its share of attention in the form of regular maintenance. The delicate dance of components requires meticulous care, adding a layer of complexity to the operational landscape.

- The Initial Sticker Shock: While the allure of precision draws many into the CO2 laser cutting realm, the initial investment can send shockwaves through budget considerations. It’s a hurdle, especially for those tiptoeing into the domain of laser craftsmanship with financial constraints.

- Learning Curve Sonata: Mastery in any craft requires time and dedication. The same holds true for the operation of CO2 laser machines. Navigating the learning curve is an odyssey, demanding patience and a willingness to unravel the intricacies of this cutting-edge technology.

- Thickness Treadmill: CO2 lasers, while versatile, occasionally find themselves on a treadmill when it comes to thicker materials. For projects demanding substantial depth, alternative cutting technologies may offer a more robust solution.

- The Ventilation Ballet: While CO2 laser machines dance through materials with grace, they generate a symphony of fumes and debris. Efficient ventilation systems become a critical accompaniment to this ballet, introducing an additional layer of consideration.

An Overture of Insightful Alternatives

Navigating the terrain of CO2 laser cutting’s disadvantages invites us to acknowledge the existence of alternative methods, each with its unique cadence. Waterjet, plasma cutting, or traditional machining may present themselves as worthy counterparts in specific scenarios.

In the grand tapestry of creation, where CO2 laser cutting paints vivid strokes of precision, understanding these challenges becomes a compass for artisans and businesses alike. This acknowledgment sets the stage for informed decisions, ensuring that each project finds its ideal medium of expression, whether in the whirring brilliance of a CO2 laser or the subtle hum of an alternative craft.

Why Opt for a CO2 Laser Cutter

In the realm of cutting-edge technology, choosing a CO2 laser cutter is akin to selecting a visionary companion for your creative endeavors. Let’s embark on a journey to explore the specific advantages that make CO2 laser cutters the epitome of precision and versatility.

Our exploration steers clear of overwhelming technical details, providing practical insights that resonate with both seasoned professionals and enthusiastic beginners. Real-world examples highlight the transformative impact of CO2 laser cutters on projects across diverse industries.

Let’s outline the reasons why opting for a CO2 laser cutter is a decision that resonates with the pursuit of excellence:

- Unrivaled Precision: The laser-focused accuracy of CO2 laser cutters ensures that your designs are executed with meticulous detail, offering a level of precision that elevates the quality of your projects.

- Ease of Use: Practical insights ensure that operating a CO2 laser cutter is accessible to users with varying levels of experience. The learning curve is manageable, enabling users to master the machine efficiently.

- Limitless Creativity: Real-world examples showcase how CO2 laser cutters empower creators to push the boundaries of creativity. From intricate architectural models to personalized branding materials, the possibilities are limitless.

| Feature | Advantages | Considerations |

| Precision | Unrivaled accuracy in intricate designs. | Ensure power and speed settings match project requirements. |

| Versatility | Seamlessly works with diverse materials, expanding possibilities. | Check compatibility with the materials you frequently use. |

| Time Efficiency | Reduces production times, contributing to project efficiency. | Assess the cutting speed in relation to project deadlines. |

| Ease of Use | User-friendly operation suitable for various experience levels. | Verify the learning curve aligns with your proficiency level. |

| Creativity Limits | Empowers limitless creative expressions and project types. | Consider the complexity of your envisioned projects. |

| Work Area Dimensions | Provides flexibility with a spacious work area. | Ensure it accommodates the size of materials you plan to use. |

| Software Compatibility | Seamless integration with popular design software. | Confirm compatibility with the design tools you prefer. |

| Ease of Maintenance | User-friendly maintenance protocols for longevity. | Evaluate maintenance requirements and frequency. |

| Budget Considerations | Affordable pricing in alignment with financial parameters. | Include potential maintenance expenses in budget planning. |

Bringing Creativity Home with CO2 Laser Machines

In the realm of personal craftsmanship, CO2 laser cutting machines have transcended the boundaries of industrial use, making their way into our homes in more compact forms. These mini versions, designed for personal use, have unlocked a world of creative possibilities, bringing the joy of laser-cutting projects directly into our living spaces.

The accessibility of mini CO2 laser cutting machines is a game-changer. No longer confined to industrial workshops, these scaled-down versions cater to DIY enthusiasts and hobbyists, making the once-unreachable technology readily available to everyone. The joy of creating unique projects at home has never been more tangible.

Imagine the delight of crafting personalized items, intricate decorations, or custom gifts—all achievable with mini CO2 laser machines. The simplicity of operation and user-friendly interfaces ensure that even beginners can embark on their creative journeys without feeling overwhelmed.

Navigating the Labyrinth of CO2 Laser Cutting Machines: Crafting Your Perfect Symphony

Selecting the right CO2 laser cutting machine is akin to composing a symphony—each note, a crucial factor in the masterpiece of your craft. Let’s embark on this artistic journey, providing not just tips but the very essence of considerations that will harmonize with your specific cutting needs.

Decoding the Melody of Crucial Factors

- Power Play: The wattage of a CO2 laser machine is the overture to its capabilities. Understanding the power dynamics ensures your machine resonates perfectly with the materials you intend to sculpt. It’s the first stanza in the ballad of precision.

- Bed Size Ballet: The canvas on which your laser dance unfolds matters. The bed size dictates the expanse of your creative tapestry. Consider your typical project sizes—whether petite portraits or grand engravings—and let the bed size harmonize with your artistic ambitions.

- Software Serenade: Behind every laser’s graceful movement is the orchestrator—the software. A user-friendly interface that seamlessly integrates with your creative vision becomes the conductor of your symphony. Consider the software’s intuitiveness, compatibility, and the symphony of design features it offers.

- Speed and Acceleration Sonata: In the world of laser cutting, speed is more than a metric; it’s the rhythm of efficiency. Delve into the machine’s speed and acceleration parameters, ensuring they resonate with the tempo of your production requirements.

Crafting Your Artistic Resonance

1. Hands-On Harmonization: Before committing to your machine duet, engage in hands-on experiences. Attend demonstrations, witness the machine in action, and feel the hum of its operation. This tactile approach tunes your understanding and connects you with the very soul of the machine.

2. Budgetary Symphony: While the allure of cutting-edge technology is undeniable, it must align with the cadence of your budget. Crafting a financial symphony involves not just the initial investment but the entire life cycle costs, ensuring a harmonious fiscal melody.

Considerations – Sculpting Your Unique Harmony

1. Material Maestro: Different materials resonate with different frequencies. Ensure your chosen machine harmonizes with the materials central to your artistic repertoire—be it wood, acrylic, or the entire spectrum of substrates.

2. Future-Proofing Crescendo: Artistic evolution is inevitable. Consider a machine that not only fits your current needs but scales with your creative crescendo. Future-proofing ensures your investment remains in tune with the evolving nuances of your craft.

In the grand symphony of CO2 laser cutting, choosing the right machine is composing the magnum opus of your artistic journey. May your selection be a harmonious convergence of technology and creativity, producing a masterpiece that resonates through the halls of craftsmanship.

Creative Ideas for Mini CO2 Laser Cutting Machines

Unique Stationery: Create custom notebooks, bookmarks, or even personalized pens to make your stationery stand out.

Fashion Accessories: Design and cut your own earrings, pendants, or unique accessories to complement your style.

Educational Aids: Craft visually appealing learning tools for children, such as puzzles, flashcards, or 3D models for educational purposes.

Holiday Decorations: Personalize your celebrations with laser-cut decorations for birthdays, holidays, or special occasions.

The Symphony of Success: CO2 Laser Cutting Unleashed

In the grand orchestration of craftsmanship, CO2 laser cutting emerges as the virtuoso, not just for businesses but also for the spirited DIY maestros. Let’s explore the harmonies it brings to both realms, creating a symphony of endless possibilities.

For the Business Crescendo:

- Precision Sonata: In the business domain, precision is the heartbeat. CO2 laser cutting conducts a precision symphony, ensuring immaculate cuts and engravings. From intricate designs to corporate branding, the laser’s finesse becomes the conductor of perfection.

- Versatility Overture: Businesses are dynamic, requiring versatile tools. CO2 laser cutting machines unfold a tapestry of versatility, seamlessly transitioning from acrylic signage to wooden branding, offering a kaleidoscope of possibilities for diverse industries.

- Efficiency Ballet: The tempo of business demands efficiency. CO2 laser cutting, with its swift and accurate choreography, enhances production efficiency. It’s not merely a machine; it’s the rhythm section, orchestrating a seamless dance of productivity.

For the DIY Symphony:

- Creative Liberation: DIY enthusiasts are bound by the chains of creativity, and CO2 laser cutting liberates their artistic spirit. From personalized gifts to bespoke home decor, the laser becomes the brushstroke in their imaginative canvas.

- Accessible Artistry: CO2 laser machines bring the once-unreachable artistry to the hands of DIY enthusiasts. It transforms garages into workshops and unleashes the potential for creating, innovating, and crafting with a level of precision that was once reserved for seasoned artisans.

- Empowering Crescendo: Entrepreneurs and hobbyists are not just dreamers; they are visionaries. CO2 laser machines empower them to transform visions into tangible ventures. The laser becomes the artisan’s chisel, carving entrepreneurial dreams into reality.

In the grand auditorium of craftsmanship, CO2 laser cutting stands as the unifying melody, harmonizing the precision needs of businesses and the creative aspirations of DIY enthusiasts. Whether crafting the future of industry or sculpting personal passions, CO2 laser technology is the resonant key that unlocks a world of endless possibilities.